Products

Fully Automated Tire Recycling Machine

- The Fully Automated Tire Recycling Machine is a piece of highly efficient and eco-friendly industrial equipment that transforms end-of-life tires into high-value products like rubber granules, steel wire, and fiber through physical crushing and fine separation technology.

Equipment Description

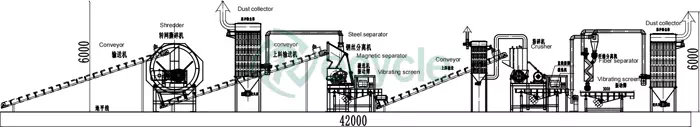

Addressing the global accumulation of waste tires, the Fully Automated Tire Recycling Machine presents a revolutionary solution. This advanced recycling machine integrates a bead wire puller, shredder, multi-stage crusher, and fine separation equipment, enabling fully automated from whole tire to finished granule. Through precise magnetic separation and fiber separation technologies, our tire recycling machine ensures the final output of high-purity recycled rubber granules and powder. Investing in this highly efficient recycling machine translates into substantial economic benefits for your business while fulfilling corporate environmental responsibility.

Applicable Materials and Products

Applicable Raw Materials

Waste Tires: Various specifications of end-of-life vehicle tires, including passenger car tires, truck tires, and engineering machinery tires.

Other Rubber Scraps: Other waste rubber products that meet the size and processing requirements of the machine.

Main Machine Outputs

High-Purity Rubber Granules/Powder: The primary output, with customizable sizes (e.g., 10-15mm or 0-4mm).

Recycled Steel Wire: Both bead wire and internal carcass steel wire.

Recycled Fiber: Such as nylon or polyester fiber.

Structure and Principle

The operation of this Fully Automated Tire Recycling Machine involves a highly efficient and precise physical separation process:

1.Coarse Shredding: The shredder breaks down the whole tire into rubber blocks approximately 3-8mm in size.

2.Primary Crushing & Separation: The steel wire separator further processes the blocks into 10-15mm granules while simultaneously beginning the separation of internal steel cords.

3.Magnetic Extraction: The magnetic separator extracts the majority of the liberated coarse steel wire.

4.Fine Grinding: The rubber granulator crushes the material down to the smaller 0-4mm particle size.

5.Secondary High-Precision Magnetic Separation: Another dedicated magnetic separator is utilized to remove any remaining tiny steel filaments, ensuring high purity.

6.Fiber Refinement: The fiber separator finally removes nylon/textile fibers efficiently using airflow or vibration, completing the final purification step.

Equipment Advantages

Investing in and utilizing this highly efficient Tire Recycling Machine offers the following significant advantages:

High Level of Automation: Featuring truly Fully Automated operation, the recycling machine drastically reduces reliance on manual labor, ensuring the production line's continuity, stability, and high capacity.

Exceptional Output Purity: By employing multi-stage magnetic separation and an advanced fiber separation technology, this machine guarantees that the final rubber granules/powder achieve high purity, meeting international standards for high-grade recycling applications.

Environmental and Resource Benefits: As a core recycling machine, it converts waste materials into valuable resources—rubber, steel wire, and fiber—aligning with sustainability goals and creating new profit growth points for the enterprise.

Modular and Flexible Customization: The machine is designed to be modular, allowing for flexible configuration and upgrade of the equipment combination based on customer needs for the final product size (e.g., 10mm or 4mm granules, or finer powder).

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou