News

Automated Solar Panel Disassembly Equipment/Line

Time:2023-10-18 15:53:12

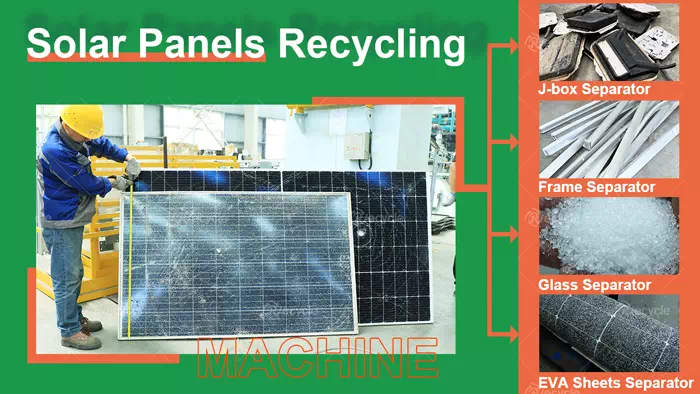

In an era of increasing environmental awareness, proper disposal and recycling of solar panels has become very important. Automated solar panel disassembly equipment/production lines have become a key solution for efficient and sustainable recycling of valuable materials from decommissioned solar panels. This article explores the benefits of automated disassembly, highlighting key components of equipment/production lines and highlighting its positive impact on the environment. Join us as we dive deeper into the world of automated solar panel recycling.

Automated solar panel removal equipment/production lines offer many advantages over manual methods. First, they significantly increase the efficiency and speed of the recycling process, thereby increasing throughput and reducing labor requirements. Second, automated equipment ensures improved worker safety by minimizing exposure to hazardous materials during disassembly. In addition, automated production lines can increase the recovery rate of valuable materials such as silicon wafers, silver, aluminum and glass, which can be reused in the production of new solar panels. Finally, the use of automated equipment/production lines helps maximize material recovery and minimize overall environmental impact, thereby reducing waste generation.

Automated Solar Panel Disassembly Equipment

Automated solar panel disassembly equipment/production lines consist of several key components that work together seamlessly. Robotic arms and grippers are used to accurately transport and manipulate panels. Advanced vision systems equipped with machine learning algorithms help identify and classify different components. Mechanical separators and shredders effectively separate glass, battery and backsheet materials, ensuring maximum recovery of valuable resources. Conveyor systems are used to handle materials smoothly and optimize the workflow within the disassembly line.

The disassembly process in automated production lines usually involves several steps. It starts with collecting and sorting the solar panels, ensuring they are sorted correctly based on size, type and condition. The automated system then removes the frame and connectors before separating the glass, battery and backsheet materials. This step utilizes cutting-edge technology to ensure high precision and minimize the loss of valuable material. Finally, automated production lines help recycle valuable metals and materials that can be reintroduced into the manufacturing process, reducing the need for virgin resources.

Automated solar panel disassembly equipment/production lines provide an efficient and sustainable solution for recycling decommissioned solar panels. By maximizing material recycling, reducing waste generation and ensuring compliance with environmental regulations, these automated systems play a vital role in the transition to a greener, more sustainable future. Automating solar panel removal is not only environmentally responsible, but also economically beneficial. If you have any questions or consultation needs about scrap solar panel recycling related equipment, please feel free to contact us.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou