Products

Lithium Ion Battery Recycling Line

- Lithium battery mainly consists of shell positive electrode negative electrode electrolyte anddiaphragm. The positive electrode is formed by coating

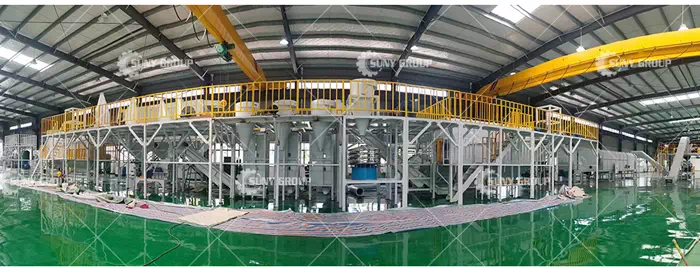

HenanRecycle is committed to researching the treatment process of used lithium-ion batteries, and has developed a complete set of waste lithium-ion battery disposal process solutions and special equipment configurations to achieve a more environmentally friendly treatment method. Our process solutions and equipment can recycle nearly 95% of the valuable components in used lithium batteries, such as casings, copper, aluminum and black powder.

RAW MATERIALS

The lithium battery recycling plant is used for dismantling and recycling the Soft package battery, cellphone battery,Shell battery,Cylindrical battery etc. Different types of lithium bat-teries have different recycling procedures. Please contact us for detailed configuration.

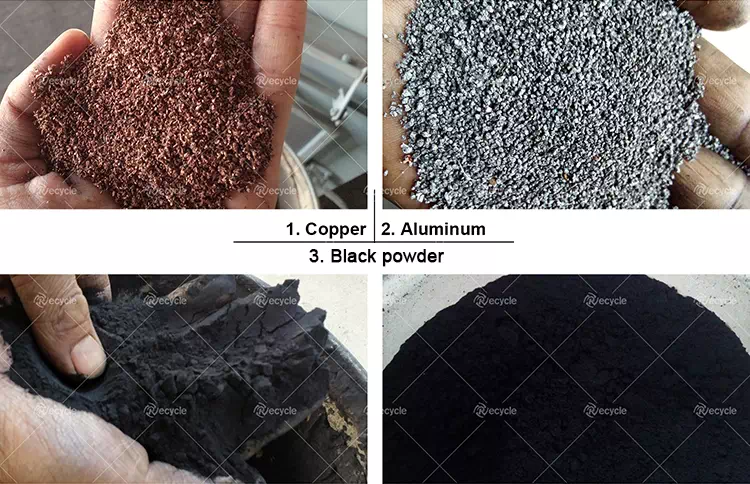

FINAL PRODUCTS

The final products of this plant is Graphite powder, Cobalt acid lithium,Aluminum and copper.

Technological Process

The pretreatment process of Lithium Batetry Recycling Plant mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.Shredder -- Hammer Crusher -- Grinder -- Separation Machine -- Collector--Pulse Purifier -- Classifying Screen -- Magnetic Machine --Gravity Separator -- High-pressure Blower

Shredder: Shredded lithium batteries into smaller pieces.

Hammer crusher: For the secondary crushing of shredded materials.

Grinder: For the grinding of the crushed materials.

Separation Machine: Separate the materials after being ground.

Collector: Collect and release the dust .

Pulse Purifier (Air Cleaner): Clean all the dust produced during the operation of the wholesystem.

Classifying Screen:Screen the materials sorted by the separation machine,and screen out oflarger metal materials.

Magnetic Machine: Separate nickel from the metals.

Gravity Separator:Separate those finer materials got from the screening machine and separatethe metal completely.

High-pressure blower: Keep the whole system in a negative state so as to collect the materialsand purity the air .

Technical Parameters

| Model | Capacity | Powder | Size(m) |

| LDC-500 | 500kg/H | 361kw | 40*11*8 |

| LDC-1000 | 1000kg/H | 442kw | 50*12*8 |

Note:

Working voltage:380±10V(415V ,440V also can be custom);

We work with WEEE recyclers around the world to provide them with innovatively designed lithium-ion battery crushing and separation equipment to recycle lithium-ion batteries efficiently and successfully. We have state-of-the-art facilities equipped with new technologies and research processes. By adopting special processes and new designs, we provide WEEE recyclers with a complete set of used lithium-ion battery crushing and sorting equipment to effectively and sustainably process used lithium-ion battery waste. Our goal is to bring the recycling and processing of used lithium-ion batteries to a new level and contribute to environmental protection and resource recycling.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou