News

How to recycle lithium batteries and turn waste into treasure

Time:2022-08-05 17:01:14

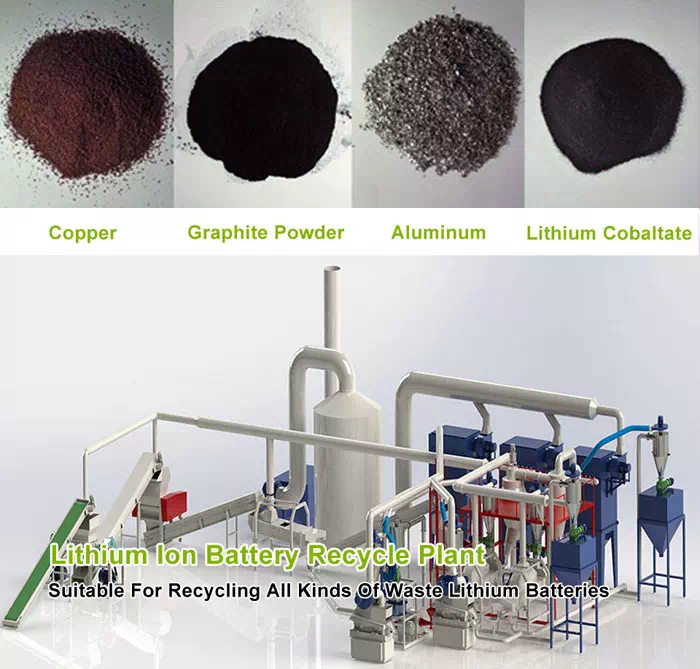

The battery production process is also consuming domestically scarce non-ferrous metal resources such as lithium, nickel, cobalt, mercury, and cadmium. Recycling used batteries can greatly alleviate the shortage of metal resources and solve problems such as ecological and environmental pollution. How to recycle and reuse used lithium batteries?

After the waste lithium-ion battery is completely discharged, the primary crushing treatment is carried out. Before sending it to the next process, it needs to be screened. If it does not meet the size requirements, it will continue to be crushed. After the initial crushing treatment, it will be crushed again. The crushing process will continue if the size requirements are not met.

After the crushing treatment, the air separation treatment will be carried out, and the diaphragm in it will be sent out through the air, and the gas during the air separation treatment will be subjected to pulse dust removal treatment.

Lithium Battery Recycling Plant

The remaining small amount of diaphragm, electrolyte, binder and other organic substances are harmlessly carbonized by low-temperature oxygen-lean carbonization, which can reduce the oxidation degree of copper and aluminum, and the carbonized material is cooled.

The cooled material enters the powder sorting system to separate the positive and negative black powder, and the remaining material is sent to the friction dispersing system to fall off a small amount of positive and negative powder attached to the copper and aluminum, and the treated material is dispersed by friction Under the condition of wind generated by the system itself, it is transported to the coarse and fine separation system to separate the positive and negative electrode powder and copper and aluminum sheets, and the separated positive and negative electrode powder.

The powders generated during the treatment are sent to the positive and negative powder sorting subsystem, and the powders aggregated by the positive and negative electrodes are collected by wind separation; the flue gas enters the multi-tube dust collector, and then enters the cooling equipment for cooling. The flue gas and the gas generated by the treatment enter the bag filter, and the flue gas after passing through the bag filter enters the basic spray tower to remove the acid gas, and then enters the activated carbon adsorption tower to remove a very small amount of organic waste gas, which is then discharged.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou