News

Introduction of waste lithium battery recycling process

Time:2023-05-25 15:40:23

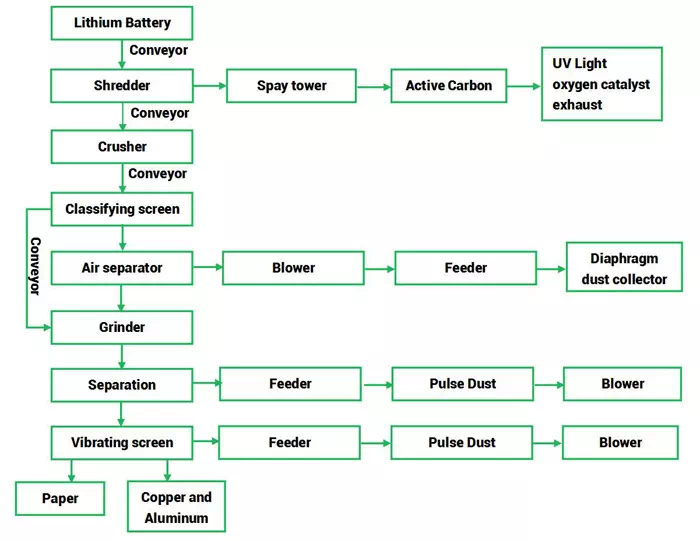

At present, the research on the recycling of waste lithium batteries is mainly focusedontherecovery of high-value anode precious metals cobalt and lithium. Copper in the negativeelectrodeof waste lithium battery (content up to 35%) is an important production rawmaterial widelyused.Based on the structural characteristics of lithium batteries, our company adoptsanenvironmentally-friendly physical separation process to realize efficient separation andrecoveryofwaste lithium batteries. The pretreatment process of scrap lithium batteries is mainly to recycle waste batteries. Afterdischarging, mechanical equipment is used to break, magnetic separation, air separation, crushing,gravity separation, screening and other processes, so that the powder on the anode andcathodecan be effectively separated from copper and aluminium foil.

Raw Material:

The Iphone Battery Li Ion Battery Recycling Equipment is used for dismantling and recyclingthesoftpackage battery, cellphone battery, shell battery, cylindrical battery etc. Different types of lithiumbatteries have different recycling procedures.

Before Start this LIB recycling business, you may consider:

1. Do you have a stable supplier of waste lithium ion batteries?

2. Are your local strict on the environmental protection requirements ?

3. Our plant capacity: 100kgph;300kgph ; 500kg/h, 1,000kg/h;2,000kg/h;3,000kg/h;more bigger.etc...

Final Products:

The final products of Iphone Battery Li Ion Battery Recycling Equipment is black mass, aluminumand copper.

TECHNOLOGICAL PROCESS:

Shredder -- Hammer Crusher -- Grinder -- Separation Machine -- Pulse Dust Collector -- ClassifyingScreen -- Magnetic Machine -- Gravity Separator -- High-pressure Blower

Machine Operation Principle:

Belt Conveyor: Convey batteries to the Shredder, Crusher or Grinder.

Hammer Crusher: Crush the batteries to the small pieces, and separate the battery cover, cathode and anodematerial at the meantime.

Shredder: Shred the fully discharged batteries.

Belt Conveyor: Convey the material to next machine after crushing.

High Magnetic Separator: After the battery crushing, the magnetic separator will remove the ferrous metal insidethematerial.

Vibrating Screen Classifier: Separate the material according to the size. Will get several type of material based on thesize.

Separation Machine: Separate the material according to its weight. Separate the lighter material (powder) fromtheheavier material (metal).

Pulse Dust Collector System: Collect the dust and plastic material after crushing when the operation, purify the air andprovideagood working environment.

Induced Draft Fan: Air flow is generated through the rotation of the turbine to collect and flow dust or materialsintheoperation of the equipment.

Grinder: Through the high-speed operation of the broken material or anode and cathode platefor rapidstrike, so that the anode plate and active material separated.

Airflow Separator: According to the specific gravity of the materials, the mixed materials of metal particles andpowderseparated by the Vibrating Screen Classifier are sorted. The weight of copper metal is greaterthanthe aluminum metal to achieve the separation of Copper and Aluminum

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou