News

Lithium battery positive and negative recycling equipment

Time:2023-02-07 15:49:57

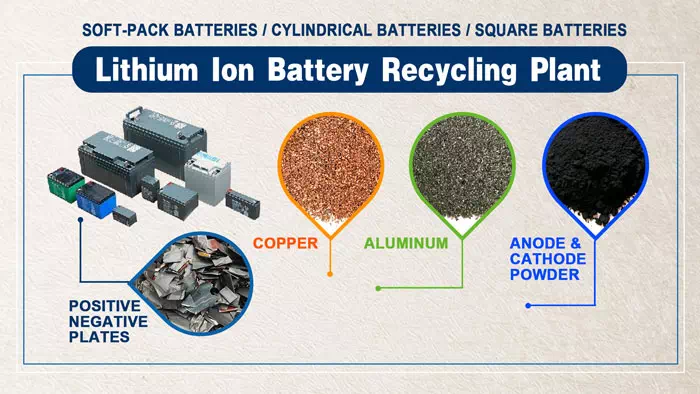

Compared with traditional batteries, lithium batteries have the advantages of light weight, high energy, high battery voltage, wide operating temperature range, and long storage life. They are currently mainstream products in the battery market and are widely used in new energy vehicles, energy storage, light-duty Strategic emerging industries such as electric vehicles, electric tools, and the Internet of Things. The increase in the number of uses will also lead to an increase in the number of used lithium batteries.

Positive and negative plates of scrap lithium batteries

Random disposal of waste lithium batteries will not only cause environmental pollution, but also cause serious waste of resources, because lithium, cobalt, manganese, copper, aluminum, iron, separators and other materials in waste lithium batteries are all recyclable materials. Recycling will inevitably lower battery manufacturing costs and ensure downstream economic profit margins.

The recycling of waste lithium batteries can also be carried out directly without discharge treatment, and directly carries out oxygen-poor crushing treatment. Through shredding, crushing, anaerobic cracking, screening, high-speed friction sorting and other processes, the metal powder of the battery pole pieces can be collected, and then Send the charged positive and negative electrode powder into the anaerobic cracking system for anaerobic cracking.

Waste Lithium Battery Recycling Equipment A recycling method for lithium-ion battery pole piece materials with simple process and low energy consumption includes: extruding pole piece powder and sieving to obtain cake-shaped current collector metal particles on the sieve and electrodes under the sieve Material powder; pole piece powder is the powder obtained by pulverizing the positive pole piece or the negative pole piece. Include the following steps:

Recycling of positive and negative plates of scrap lithium batteries

1) Discharging the recovered lithium-ion battery, discharging the electrolyte, disassembling to obtain the negative pole piece, and then pulverizing the obtained copper pole piece to obtain the negative pole piece powder with a mesh size of 50-100 mesh;

2) Separate about 95% (accounting for the mass percentage of the positive electrode material fine powder) metal copper substrate from the negative electrode sheet powder obtained in step 1) by winnowing first, and then screening, and the rest is copper containing about 5 % (accounting for the mass percent of negative electrode material fine powder) negative electrode material fine powder;

3) Using a 300-mesh roller mill to grind the fine powder of the negative electrode material, and then sieve it with a 300-mesh ultrasonic vibrating sieve to obtain the cake-shaped current collector metal copper particles a on the sieve and the negative electrode material powder a under the sieve;

4) The negative electrode material powder a obtained in step 2) is rolled with a 500-mesh roller mill, and then sieved with a 500-mesh ultrasonic vibrating sieve to obtain the current collector metal copper particles b and the negative electrode material powder b with higher purity;

5) The negative electrode material powder b obtained in step 3) is rolled with an 800-mesh roller mill, and then sieved by an 800-mesh ultrasonic vibrating sieve to obtain the current collector metal copper particles c and a higher purity negative electrode material powder; wherein The purity of negative electrode material powder can reach more than 99%;

6) Mix the copper particle a obtained in step 3), the copper particle b obtained in step 4) and the copper particle c obtained in step 5).

The recycling method of lithium-ion battery pole piece material has a simple process, because the pole piece material is easy to fall off from the current collector fluid and become powdery during the crushing process, while the current collector fluid fragments are easy to agglomerate into balls or blocks Particles; Utilizing the good ductility of metal aluminum and copper, the crushed pole piece fine powder is extruded, the aluminum particles or copper particles in the pole piece powder will be extruded into cakes, and other particles will be further pulverized into Finer particles, and then the cake-shaped aluminum particles or copper particles are separated from other particles by sieving, which not only improves the purity of the obtained electrode material powder, but also improves the recovery efficiency of aluminum or copper, and the whole process does not require Any chemical reagents will not produce secondary pollution.

Firstly, the pole piece powder is sorted to remove large-sized current collector debris particles, and then the remaining electrode material fine powder is extruded. Sorting can be done by screening, or by winnowing and then screening. About 95% (mass percentage) of the current collector can be separated from the electrode powder by winnowing first and then screening, but there are still about 5% of the total mass of the remaining electrode material fine powder mixed into the positive/negative electrode. Pole powder.

The particle size of the electrode powder is less than 5mm. More preferably, the particle size of the pole piece powder is 50-100 mesh. Sorting is first wind-selecting the pole piece powder, and then screening. Extrusion is roll pressing or roll milling. Roll pressing adopts a roller pressing machine. The roller mill adopts a roller mill. The mesh number of the roller mill is the same as the mesh number of the sieve used for screening. Sieving is sieving by ultrasonic vibrating sieve. The method for recycling the pole piece material of the lithium ion battery further includes: repeatedly extruding and sieving the obtained pole piece powder. Extruding and sieving multiple times can further improve the purity of the electrode material powder, and can increase the recovery rate of aluminum or copper. Roller mills are used for extrusion, and when roller milling and sieving are repeated, the mesh size used for roller milling and sieving is smaller than the previous mesh size. If you have more questions about lithium battery recycling, you can contact us at any time, and we will have professional technicians to give you detailed answers.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou