News

PCB crushing and separation recycling production line

Time:2022-12-13 15:45:52

With the industrialization of PCB processing, scale, and the wide application of electronic products, human social production and life activities generated and manufactured more and more electronic waste.

Waste PCB, containing lead, mercury, hexavalent chromium and other heavy metals, if discarded at will, and, PCB also contains polybrominated biphenyls (PBB), polybrominated diphenyl ether (PBDE) and other toxic chemicals as components of flame retardants, not only will cause pollution to the environment soil, water resources, potentially harmful to human health, but also caused by the waste of resources, it is difficult to recycle. Scrap PCB, containing nearly 20 kinds of non-ferrous and rare metals, has a high economic value of recycling.

Therefore, the correct treatment of waste PCB circuit boards, especially important.

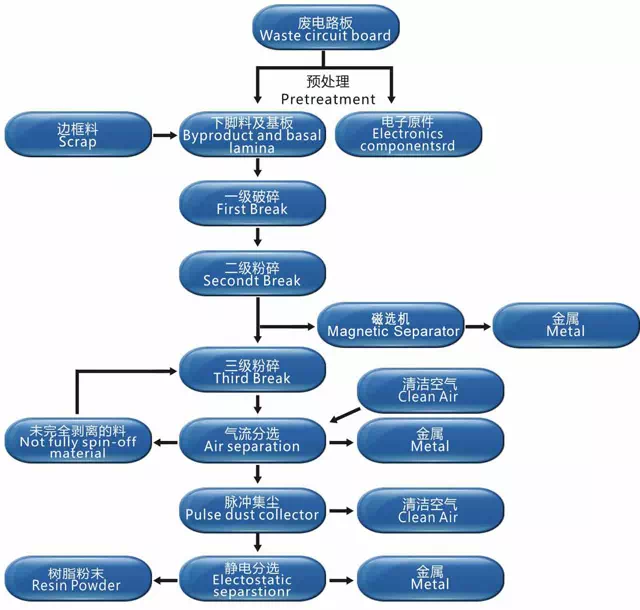

The circuit boards are separated and recycled through the waste circuit board disassembly and crushing sorting technology. The change technology equipment is suitable for the recycling of various circuit boards, circuit boards, FPC flexible circuit boards and other electronic waste. The process contains electrical components of circuit boards, circuit boards and other raw materials without disassembly, through the crushing, metal separation technology can get the metal material in the circuit board This waste circuit boards, circuit boards can be directly into this production line processing production. Materials through a coarse crushing, magnetic separation, secondary fine crushing, dust collection, wind separation, vibration screening, specific gravity sorter, electrical separation and other processes to separate and recover, the recovery rate of up to 99% or more. The process is automatic from feeding to the end of sorting, requiring only 1-2 people to operate. The process is a physical dry separation, without heating, incineration, water and chemical materials, low cost, high efficiency, without any pollution of room temperature dry separation. These can be widely used in electric power, mining, manufacturing and office automobile parts and crafts after recycling through equipment processing.

Features of the scrap circuit board separation equipment:

1. circuit board electrostatic separation equipment uses an advanced mechanical crushing, high-voltage electrostatic separation of new technology. After crushing and dissociation, the separation of metallic and non-metallic materials is carried out with high purity;

2. the key technology is the organic combination of a variety of special crushing and dissociation equipment for waste circuit boards, in the production process to achieve greater energy-saving effect, and to achieve a high rate of metal separation;

3. the comprehensive performance of the circuit board electrostatic separation equipment, for computer boards, computer boards, TV boards and other circuit control boards have a unique effect. It also has the same effect on the recovery of various circuit boards containing capacitor parts;

4. this production line is the wind selection type products upgrade products, than the wind selection type power consumption is reduced, and no noise, less manual automation procedures, high efficiency, while covering an area of smaller, is the waste electricity (line) circuit board recycling to the most ideal production line;

Circuit board recycling is an important part of the e-waste recycling process, SUNY GROUP is a professional e-waste recycling equipment manufacturing and solutions provider, including the pre-electronic waste disassembly and classification, as well as the late e-waste precious metal extraction, also has a wealth of experience and equipment, if you need, welcome to contact us at any time for advice.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou