News

Waste aluminum-plastic packaging separation and recycling equipment

Time:2023-02-21 15:44:07

There are a large number of aluminum-plastic packaging such as food packaging bags and beverage bottles and tablet plates in the market. The main components of these aluminum-plastic packaging products are plastic film and aluminum foil mixture. Aluminum-plastic separation and recovery equipment crushes, grinds and separates different packaging materials more cleanly and thoroughly, uses physical and mechanical methods to crush waste aluminum-plastic packaging products into granules or powder, and uses electric fields to separate the materials according to the conductivity characteristics of aluminum and plastics Its environmental separation process and working principle are as follows:

Aluminum and plastic recycling

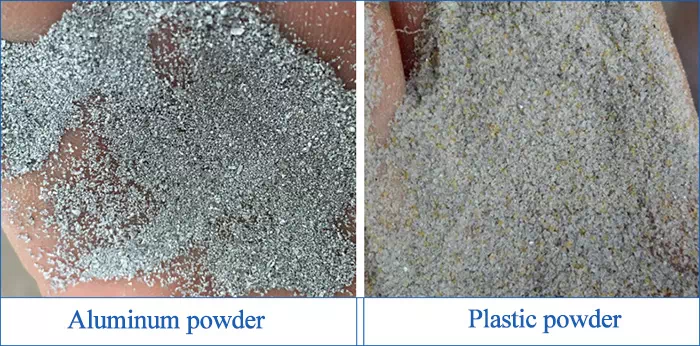

1. The environmental protection separation process is roughly as follows: crushing, breaking the metal and plastic compound into granules; grinding and decomposing, grinding the granules into a metal and plastic mixture; electric separation, the metal and plastic mixture, electric separation Separation into metal and plastic; the purity rate of the separated aluminum scrap can reach more than 99%.

2. Use a pulverizer to crush the waste materials into particles of a certain size (in order to avoid the high temperature generated from affecting the efficiency of plastics and aluminum). Shear forces separate the aluminum and plastic particles.

Installation site of aluminum-plastic separator for Korean customers

3. Since aluminum is a conductor with good electrical conductivity, but plastic is not a conductor, when the mixed particles of aluminum and plastic fall into a rotating grounded roller, and a high-voltage electrode is fixed above the roller to provide a stable state for the crushed particles The electric field, aluminum and plastic particles are polarized simultaneously. When they leave the electric field area, the aluminum particles will lose their charge rapidly, while the plastic particles are still charged. Under the action of centrifugal force and gravity, the aluminum particles are thrown out of the roller, and the plastic particles fall along the roller.

Working principle: After the medicine board enters the crusher, it becomes flakes below 10mm, and then enters the high-speed water-cooled turbine pulverizer to chop the material into fine pieces. The materials that meet the requirements are screened by the rotary vibrating screen. The principle of the electrostatic separator separates aluminum and plastic, and the unqualified ones are returned to the mill to repeat the process. The loss of aluminum and plastic is very low, and the recycling rate of aluminum is close to more than 99%. And will not cause secondary environmental pollution. The aluminum particles separated by the aluminum-plastic separation and recovery equipment can even be sold directly, with good economic and social benefits.

The equipment has a variety of models and separation modes, which can meet different material requirements, and has a good separation effect on 2-5 kinds of mixed plastic crushed materials.

The equipment is designed with an intelligent touch screen, and the operation is relatively simple. The entire sorting line only needs 1-2 people to work. Multiple and stable sorting modes can separate plastic mixtures quickly and with high quality, and the sorting accuracy can reach 99%. +. After sorting, the plastic can be sold.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou