Products

Laminated Glass Recycling Machine

- Dedicated Laminated PVB Glass Separation Machine for high-value recycling of auto windshields and architectural glass, achieving 99% interlayer-glass purity.

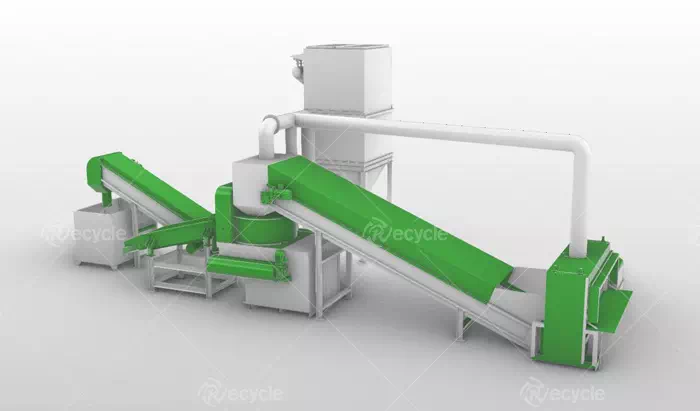

Equipment Description

This advanced system is specialized for reclaiming PVB film from various laminated glasses, including end-of-life automobile windshields. It comprises two core components: a Glass Pre-Pressing Machine and a PVB Glass Separator. Utilizing PLC control and robust double-roller technology, the line ensures stable, pollution-free processing to output complete, undamaged PVB interlayers and clean glass particles, maximizing material reuse value.

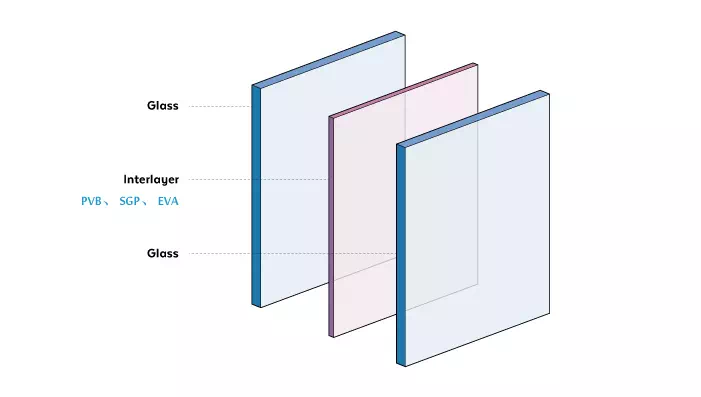

Introduction of Laminated Glass

Laminated glass is a flat or curved composite glass product formed by heating and pressing an organic polymer interlayer film between two or more original glass sheets. Common original glass sheets include float glass, tempered glass, colored glass, heat-absorbing glass or heat-reflecting glass, etc.; common interlayer films include PVB, SGP, EVA, etc.

Applicable Materials

Applicable Materials (Expanded)

The equipment is designed to process a variety of laminated glasses, including:

1. PVB Laminated Glass: The core material, widely used in vehicle applications (e.g., auto windshields) and architectural projects across Europe and America.

2. SGP Laminated Glass: Primarily used for high-performance structures like glass lighting roofs, exterior windows, and curtain walls.

3. EVA Laminated Glass: Mainly utilized for interior partitions and decorative glass.

Final Material Output

After separation, the final output includes:

1. Clean Glass Particles: Achieving up to 99% removal of the laminate glass from the film.

2. The whole PVB/SGP/EVA Interlayer: The complete film is recovered in its original shape.

3. Key Advantage: The process is meticulously controlled to not damage the interlayer, ensuring the film maintains its original shape for high-quality secondary use.

Machine Advantages

1. Highly stable separation process guarantees that the PVB/SGP/EVA film is recovered intact and in its original shape, unlike other methods that damage the interlayer.

2. The Press Machine (Double-Roller Compactor) handles a maximum feed size of 1500mm. The entire line is available for customization with European standard Schneider electrical components.

3. The production line is governed by an easy-to-use PLC system, featuring multi-language switching for seamless global operation and management.

4. Equipped with a Dust Collector and a fully enclosed conveying system, ensuring environmentally friendly and pollution-free production by efficiently managing dust and debris.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou