Products

Paper Plastic Recycling Separating Machine

- For the characteristics of paper-plastic composite material, paper-plastic mixing material adopts the method of adding water to mix and rubbing with the main shaft sieve plate to separate paper and plastic.

Product Description:For the characteristics of paper-plastic composite material, paper-plastic mixing material adopts the method of adding water to mix and rubbing with the main shaft sieve plate to separate paper and plastic. The components contain main frame, separating shaft, slurry collecting tank, driving motor, driving decoration, water injection pipeline, protective cover and so on.

SUITABLE RAW MATERIALS:Coated paper / Kraft paper bag / Tetra pak / Combibloc / Paper-plastic composite woven bag

FINAL PRODUCTS: PAPER /PLASTIC /ALUMINUM.

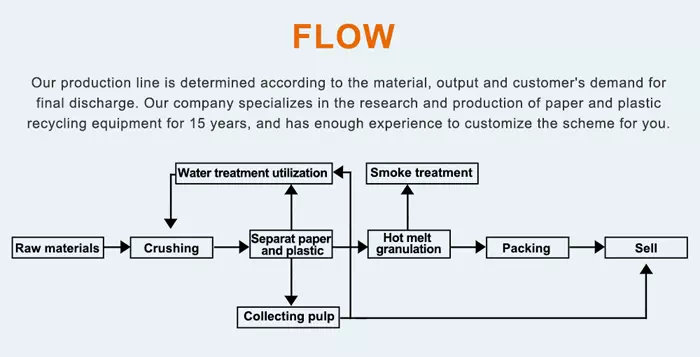

WORK FLOW:Our production line is determined according to the material, output and customer's demand for final discharge. Our company specializes in the research and production of paper and plastic recycling equipment for 15 years, and has enough experience to customize the scheme for you.

The paper plastic recycling separating machine includes main equipments:

Automatic slagging pool: the motor chain drives the spindle to rotate, and the paddle stirs the water flow to clean the impurities in the plastic, so that the bottom material can be fully separated. Automatic slagging cleaning pool using spiral structure to promote the sedimentary material extends the bottom of the movement to the slagging machine, to achieve automatic slagging. Slag cleaning pool national standard heavy-duty chain drag scraper close to the bottom scraping bottom material to the discharge port discharge, bottom material can be packaged for export.

Slag pulp separator: in waste paper pulping, due to the different paper quality of waste paper, there are a large number of slag, the machine can exclude light and heavy debris and decomposition of fibers in the small pieces of paper, does not block the sieve plate, hard debris will not hurt the sieve plate, the plant does not have to stop running often for cleaning, but also as a second bulk pulp machine. Mainly used for fiber separator and pressure screen after the tail pulp sorting; after processing and sorting of pulp directly back to the fiber separator or pressure screen before the pulp pool reuse. After sorting the exhaust tailings do not contain fiber, in line with the emission requirements of environmental protection.

Dewatering trommel screen: trommel screen is one of the general screening machines, which has the characteristics of simple structure, simple operation, and replacing the screen mesh to get different granularity materials within a certain range. It is suitable for the sorting of different granular materials. The basic principle is that the particles rotate to a certain height with the screen cylinder, and are thrown down due to gravity, and filtered through the screen mesh to form the screening. This tumbler screen is shaft drive, the screen mesh is steel wire mesh or high tenacity nylon mesh. The size of the screen holes can be configured by the user according to the process needs. The base frame is welded to each other for easy transportation and installation.

Pulp Filter Press: Pulp Filter Press is a mechanical equipment developed and designed for the recycling of pulp separated from paper-plastic separator. Using motor-driven spindle operation, drive polyester blanket, pulp through the pump to the filter press, uniform flow to the polyester blanket, through the polyester blanket driven by the polyester blanket is squeezed between the two layers of polyester blanket, through a number of press rollers squeezed dry and compacted, so as to make cardboard to facilitate the secondary use. The filtered clean water can be pumped away through the water pump for recycling, reducing emissions and saving resources.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou