Products

Industrial Spiral Pulverizer Shredder

- The Industrial Spiral Shredder for Soft Materials is a low-speed, high-torque machine engineered with anti-tangling spiral blades, making it highly effective for the efficient recycling and volume reduction of flexible waste.

Equipment Description

The Industrial Spiral Pulverizer Shredder is a high-efficiency, low-speed, high-torque crushing machine designed specifically for processing flexible, highly entangling soft materials. The machine achieves remarkable volume reduction by combining multiple forces such as shearing, tearing, and compression. It stands as an ideal solution for improving the recycling efficiency of tough, flexible waste materials.

Applicable Raw Materials

This spiral shredder demonstrates powerful crushing capability, with a maximum capacity reaching 5 tons per hour (5T/H). It can crush almost all kinds of soft materials, making it widely applicable in the recycling sector, including waste clothing, fabrics, carpets, various plastic films, packaging bags, fishing nets, PP strapping, footwear, and other flexible waste materials.

A key advantage of this equipment is its outstanding anti-tangling design. Compared to traditional double-shaft, single-shaft, or double-roller shredders, the spiral shredder uses a specially designed high-torque spiral rotor and spirally arranged blades. These features enable the machine to securely grip and cut materials while preventing them from wrapping around the cutter roll, significantly minimizing downtime and ensuring continuous, uninterrupted operation.

Structure and Principle

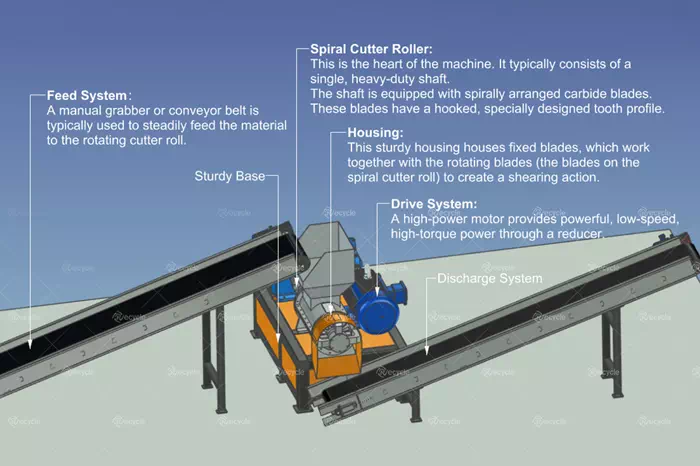

The structure of the spiral shredder is robust and reliable, primarily composed of the following key systems:

Feed System: Typically using a manual grabber or conveyor belt, this system is responsible for steadily and continuously feeding the material into the cutter area.

Spiral Cutter Roller: As the heart of the machine, it consists of a single, heavy-duty shaft equipped with specially designed tooth-profile carbide blades arranged spirally. This is the component that executes the primary shredding function.

Housing: The sturdy casing houses fixed blades that work in synergy with the rotating blades on the spiral cutter roll to create a powerful shearing action.

Drive System: Power is supplied by a high-power motor through a reducer, operating at a low speed to deliver high torque, ensuring stable performance under heavy loads.

Discharge System: Used to convey the processed material that meets the required output specifications.

Equipment Advantages

The equipment offers flexible, adjustable output size control. By replacing screens with different mesh sizes or adjusting the cutter chamber length, the size of the final product can be precisely controlled. Typical output size ranges supported include: a minimum of approximately 10 mm (min), 30 mm, and a maximum of about 50 mm (max). This adjustability allows it to meet the requirements of different subsequent recycling processes.

In summary, the core advantages of the Industrial Spiral Shredder are reflected in the following aspects:

High Efficiency & Power: The low-speed, high-torque design ensures powerful shredding capability and high efficiency.

Strong Anti-Tangling: The unique spiral blade design solves the industry challenge of soft material wrapping and tangling.

Significant Volume Reduction: The combination of shearing, tearing, and compression greatly reduces material volume, cutting logistics costs.

Environmentally Friendly: The machine's low-speed mechanism ensures low noise and low dust generation, making it suitable for operation in environmentally regulated work environments.

Durability and Reliability: Equipped with a heavy-duty frame and reliable drive components, it is designed for continuous, high-load operation, offering long-term stable performance and manageable maintenance.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou