Products

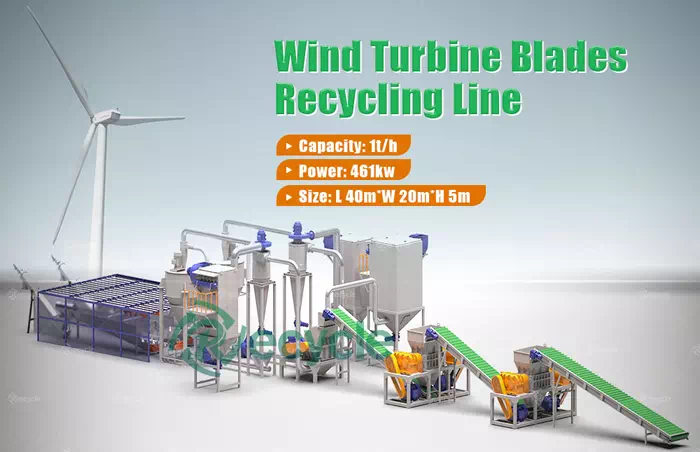

Wind Blade Recycling Machine

- The Wind Blade Recycling Machine is an advanced environmental protection system designed for the efficient recycling of wind turbine blades. It separates and reuses materials such as glass fiber, resin, and balsa wood, minimizing waste and environmental pollution while promoting sustainable resource utilization.

Equipment Description

Developed by Henan Recycle, this production line is specifically designed to handle the complex composite materials used in wind turbine blades, including glass fiber and carbon fiber. Through multi-stage crushing and sorting technology, it achieves high separation efficiency and stable performance. Equipped with PLC intelligent control, automatic alarms, and pulse dust collectors, the system operates continuously with low emissions and easy maintenance, providing an ideal solution for large-scale composite waste recycling.

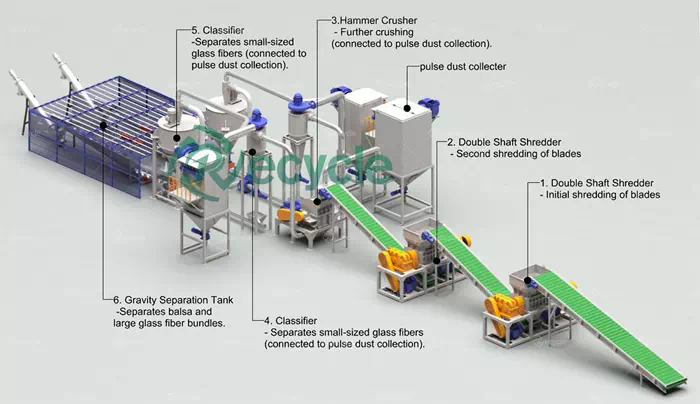

Equipment Structure

The complete line mainly includes a Double Shaft Shredder, Hammer Crusher, Three-Stage Sorting System, and Pulse Dust Collector. The Double Shaft Shredder performs coarse crushing of the blades; the Hammer Crusher further refines the material and controls particle size via a screen; the Three-Stage Sorting System achieves a 95% separation rate; and the Pulse Dust Collector efficiently removes fine dust particles. The entire line operates under PLC centralized control, ensuring continuous feeding, intelligent operation, and stable performance.

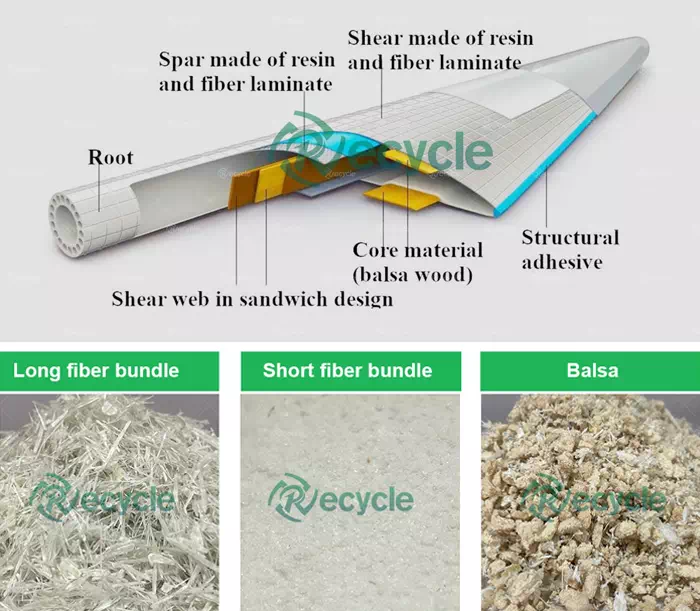

Raw Materials and Final Products (with Recycling Value)

The raw materials are discarded wind turbine blades composed of glass fiber, carbon fiber, resin, and lightweight wood core. After processing, the final products include resin powder, small fiber bundles, large fiber bundles, and balsa wood. These recovered materials can be reused in industries such as construction and composite manufacturing, significantly reducing resource waste and environmental impact. Recycling wind turbine blades not only supports circular economy principles but also creates new value from waste. For more details or customized recycling solutions, please contact Henan Recycle for technical consultation and equipment quotations.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou