News

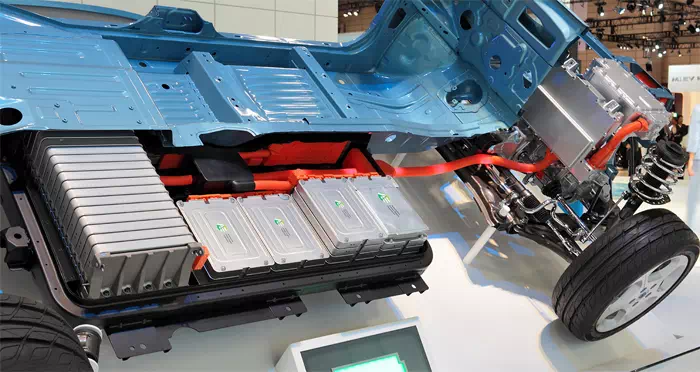

EV lithium battery recycling machine

Time:2024-04-28 16:29:15

With the rapid growth of the electric vehicle (EV) industry, the recycling of lithium batteries is becoming increasingly important, and Henan Recycle, Inc. is a leader in this field, offering a range of advanced technologies and equipment to process used lithium batteries. The following is an introduction to Henan Recycle and its lithium battery recycling technology and equipment.

Lithium Battery Recycling Equipment

The lithium battery recycling line offered by Henan Recycle is an innovatively designed piece of equipment that can efficiently and successfully recycle lithium batteries. The company has developed a new method for recovering cobalt and lithium from lithium-sulfur battery waste using mechanochemical methods. This method uses a mill to grind lithium cobaltate (LiCoO2) and polyvinyl chloride (PVC) to mechanochemically form cobalt and lithium chloride (LiCl).

Recycling process

Battery sorting and pre-processing: involves separating different types of batteries and removing the casings. Pre-processing equipment such as mechanical shredders, scissors, or crushers are used to break the batteries into smaller pieces for subsequent steps.

EV lithium battery recycling machine

Battery Shredding: Battery shredding is a key step in lithium battery recycling and helps to further reduce the size of the battery assembly. Specialized shredders are used to mechanically break the battery pack into smaller pieces.

Carbonization: Carbonization processes are used to further process battery components and recover valuable materials. These processes involve heating the battery material at high temperatures to separate it into its respective elements.

Recycling Plant Infrastructure

Lithium battery recycling plants are equipped with specialized infrastructure to address the unique challenges associated with lithium battery recycling. These facilities employ safety measures such as fire protection systems, ventilation systems, and containment areas to mitigate the risk of thermal runaway, fire, or explosion.

Reprocessing and Refining

After the initial recycling process, the recovered material may undergo additional refining to improve its purity and quality. Techniques such as electrolysis, solvent extraction, and electrolytic refining may be used to further purify the recovered metals and ensure they meet the specifications required for battery manufacturing.

Henan Recycle's lithium battery recycling technology equipment continues to evolve to improve efficiency, increase material recovery, and minimize environmental impact. The company's new processes and equipment play a vital role in ensuring the sustainable management of lithium battery waste and the conservation of valuable resources.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou