News

How do you make honeycomb paper sheets?

Time:2024-01-04 17:01:32

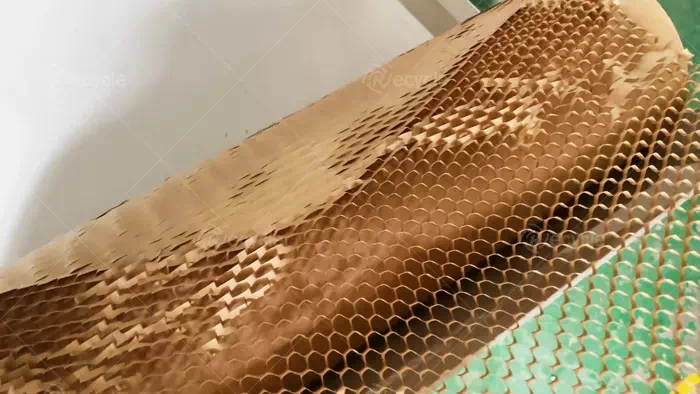

Honeycomb paper, also known as honeycomb panel or honeycomb cardboard, is a paper product with a honeycomb-like structure. Its manufacturing process involves a series of precise steps to ensure the final product has excellent strength and lightweight properties.

First, in the honeycomb paper manufacturing process, high-quality kraft paper or recycled paper is selected as the raw material. These papers have good strength and flexibility and are suitable for making strong honeycomb cardboard.

Honeycomb Paper Sheets

Next, the paper is cut into the desired large pieces, usually larger than the final honeycomb board size. These large sheets of paper will be used to form the individual layers of the honeycomb structure.

The paper then passes through a corrugating machine, which contains a series of rollers with ridges and depressions. These rollers apply pressure to press the paper into a zigzag or honeycomb structure. This process is called corrugation, and it gives honeycomb paper its unique structure.

After corrugation, the corrugated sheets are stacked on top of each other, making sure that the ridges correspond to the valleys of adjacent sheets. The adhesive between these pieces of paper comes into play, holding them firmly together to form a honeycomb structure. Apply just the right amount of pressure as needed to ensure a good bond between the paper layers.

Honeycomb Paper Making Machine

Once stacked and glued, the honeycomb paper is trimmed to the final desired size. The trimming process removes any excess material and ensures that each honeycomb board has a consistent size and shape.

Finally, the honeycomb cardboard needs to undergo a curing and drying process. This process can be accomplished by placing the cardboard in an oven for heating and drying, or by air drying. Curing and drying fully cures the adhesive and ensures the honeycomb paperboard has structural integrity and stability.

Depending on specific needs and applications, honeycomb paperboard can undergo additional finishing. For example, it can be laminated with other materials for added strength and durability. The surface can also be coated to improve waterproofing or add decorative properties.

Overall, the manufacturing process of honeycomb paper requires precise operations and high-quality raw materials to ensure that the final product has the required properties and qualities. This unique paper structure provides a lightweight, high-strength solution for areas such as packaging, construction and automotive, while also contributing to the efficient use of resources and environmental protection.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou