News

Solar photovoltaic panel recycling technology and equipment

Time:2022-11-29 14:57:13

Most of the valuable resources such as silicon, silver, copper, and aluminum in photovoltaic modules can be recycled and reused through recycling, which can save resources, reduce the mining of primary resources and reduce the energy consumption of resource extraction, thereby reducing the impact on the ecological environment and destruction. Therefore, the recycling and harmless treatment of photovoltaic modules is a matter of great concern to the international and domestic industry and environmental circles.

Taking a 250W photovoltaic module as an example, glass accounts for about 70% of the total weight, aluminum frame accounts for about 18%, and semiconductor materials account for about 4%. It appears that most of the weight of a solar module comes from recycled materials. In addition, the study also pointed out that although rare metals such as silver, indium, and gallium contained in solar modules only account for 1-2% of the total mass of the module, they still have recycling value.

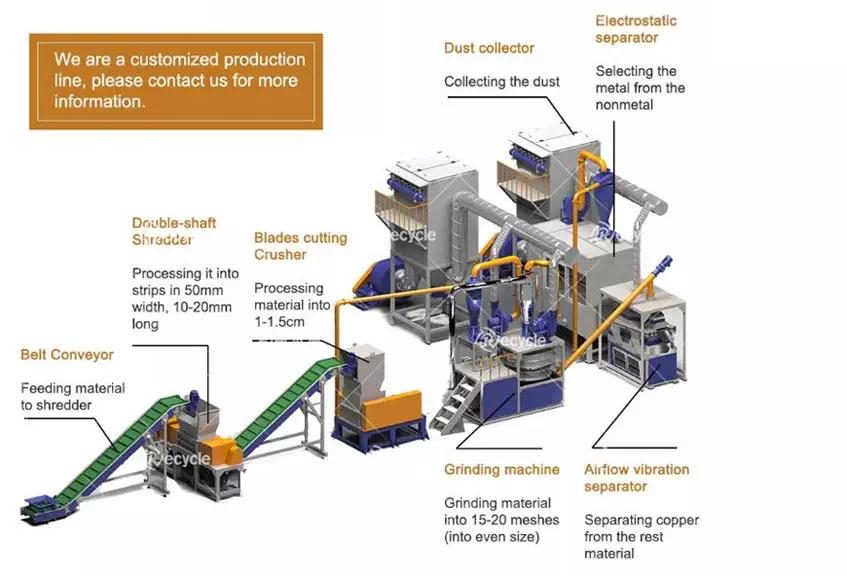

Composition of PV Solar Panel Recycling Equipment

When recycling waste photovoltaic modules, the modules need to be disassembled, and the aluminum frame, glass and junction box are partially removed to obtain silicon wafers. The physical separation method is to remove the aluminum frame and junction box of the component first, then crush the frameless component, separate the tin-coated solder ribbon and the glass particles, and then grind the remaining part to obtain metal, silicon powder, and backplane particles by electrostatic separation. and EVA particles.

Solar PV Panel Recycling Process

The solar photovoltaic panels that need to be recycled are sent to the centralized processing center. The processing center first disassembles and separates the aluminum components, which are usually concentrated in the frame of the photovoltaic panel.

The second step is to process the photovoltaic panels, the main purpose is to separate the glass, which can be separated from the panel by using a glass separator at high temperature.

The third part is crushing, which uses a twin-shaft shearing crusher to break the materials processed in the previous step into small pieces, and then conduct various screenings on these crushed materials based on physical and chemical properties to separate different materials .

In this way, different raw materials that can be reused can be obtained, environmental pollution and damage can be reduced, and economic profits can also be created.

It should be noted that solar photovoltaic panel recycling is currently an emerging industry, and related technologies are constantly changing and updating, and new technical solutions may be launched at a certain point in time.

Shredding first and then recycling is the golden rule for almost all industrial waste disposal including photovoltaic panels. SUNY GROUP Intelligent Environmental Protection specializes in the research and development of solid waste crushing and sorting technology and equipment production. The material crushing and recycling solutions we provide include various industrial waste, domestic waste, construction and demolition waste, agricultural and forestry waste, etc.

The crushing and recycling of solar photovoltaic panels is a relatively new field. We have cooperated with many customers at home and abroad to establish photovoltaic waste recycling and processing production lines. If you are interested, please contact us to introduce the relevant information to you.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou