News

Waste lead-acid battery lead smelting furnace equipment

Time:2023-02-28 15:38:08

Lead smelting furnaces are mainly used for processing and recycling lead in lead-acid battery waste, and can also be used for refining lead such as lead sulfate, lead oxide, lead concentrate, lead slag and lead ore. Lead smelting furnace equipment mainly includes sintering and roasting, blast furnace smelting and other processes in the process of refining lead.

The structural composition of the lead smelting furnace is divided into three parts: hearth, furnace body and furnace roof. Furnace body is further divided into molten pool zone and reburning zone, with molten pool tuyeres (lower tuyeres) and reburning tuyeres (upper tuyeres) on both sides. One end is the feeding chamber, and the other end is the slag siphon well and siphon lead discharge port. The slag discharge port is higher than the downwind port to form a molten pool, that is, the depth of the molten pool can be adjusted by the height of the slag port.

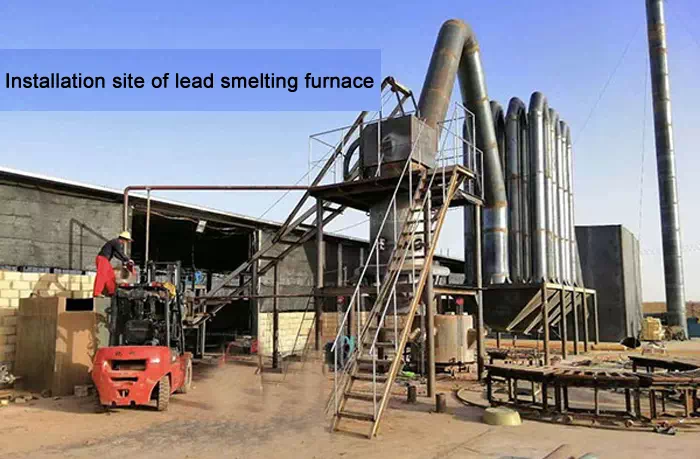

Installation site of lead smelting furnace

Lead concentrate, flux, returned dust and coal are fed into the side-blowing furnace from the main feeding port through the feeding belt, and are quickly drawn into the slag for melting, enter the tuyere belt of the smelting chamber, and then enter the upper part of the tuyere, and the bubbling formed by the blast The corresponding oxidation and reduction reactions occur simultaneously in the layer.

Lead scrap and lead ingot

Dust removal technology for lead smelting equipment:

1. Sintering dust removal: need desulfurization treatment or discharge through high chimney. The sintering flue gas is highly corrosive, and the overall temperature inside the sintering pot will change with time, and it is easy to condense, so heat preservation and anti-corrosion measures should be taken.

2. Bag-type dust removal: to 300 ℃, or even 500-600 ℃, it is necessary to take cooling measures. The bag-type dust removal system is used. The dust removal process is commonly used in a series of operation processes such as blast furnace-settling chamber-surface cooler-cyclone dust collector-fan-bag dust collector-fan-chimney. Due to the high density of lead dust and relatively high viscosity Strong, when the dust content is high, it is not suitable to use a positive pressure bag filter to prevent the dust from sticking to the fan impeller, which will greatly affect the overall quality of the lead refining equipment and greatly reduce its service life.

The above is the introduction of lead smelting equipment in the process of lead-acid battery recycling. Through lead refining, lead ingots with higher purity can be obtained, and then sold directly or further processed for use. If you have any questions or are interested, please feel free to contact us for consultation.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou