Products

UBC Aluminum Cans Paint Removing Machine

- UBC Aluminum Cans Paint Removing Machine integrates shredding, crushing, and high-temperature paint removal to recycle coated metals efficiently. Featuring a sealed low-oxidation design and advanced dust removal system, it ensures clean operation and high metal purity.

This system uses multi-stage crushing and high-temperature paint removal technology to efficiently separate and recycle waste materials such as coated metals or used cans. It offers outstanding advantages in crushing efficiency, paint removal rate, and environmental protection.

1. Double Shaft Shredder — Coarse Crushing

The double shaft shredder is designed for the coarse crushing stage. Its dual-shaft structure enables efficient shredding of various materials such as metals, plastics, and composites, preparing them for the next fine crushing process.

2. Hammer Crusher — Fine Crushing

The hammer crusher effectively breaks down caked or agglomerated materials, ensuring a uniform discharge size of 30–50 mm. This guarantees stable performance for subsequent separation and treatment steps.

3. Low Oxidation Rate — Maintain Metal Quality

The equipment features a sealed isolation belt design that prevents deformation and oxidation of materials under high temperatures, preserving the integrity and purity of the metal.

4. Environmentally Friendly Dust Removal System

Equipped with filters, fans, and exhaust ducts, the dust removal system efficiently collects and processes coked paint powders and fine dust, ensuring clean and pollution-free operation throughout the process.

5. 99.9% Paint Removal Rate — Clean and Efficient

At high furnace temperatures, the paint layer on the surface is coked and turned into fine powder, which quickly detaches from the material. Combined with the dust removal system, it achieves an impressive 99.9% paint removal rate.

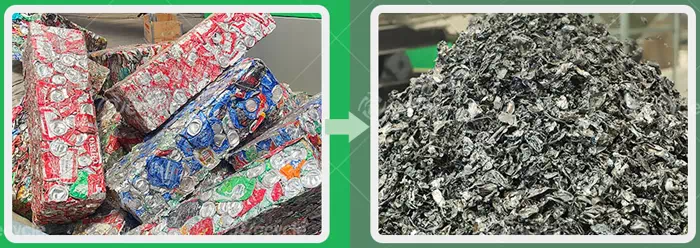

Before and after carbonization treatment

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou