News

Principle of copper electrolysis, blister copper refining

Time:2022-06-28 17:11:24

Copper is widely used in electrical, light industry, machinery manufacturing, construction industry, transportation and other fields. As far as China is concerned, copper is second only to aluminum in the consumption of non-ferrous metal materials. A large number of industrial needs, coupled with the serious shortage of copper resources, in recent years, the recycling of copper has attracted attention from all walks of life. The blister copper in the mixed metal can be refined by copper electrolytic recovery and processing equipment, and can reach a purity of 99.9 to meet various industrial needs.

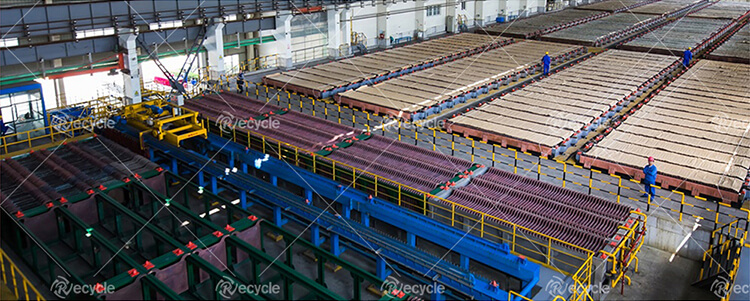

The copper electrolytic treatment and reuse equipment mainly purifies crude copper according to the principle of copper electrolysis. The separated metal part is cast into a copper electrolytic anode plate through intermediate frequency smelting for electrolytic copper. For metals and precious metals, the anode is often passivated in conventional electrolysis and the electrolysis cannot be carried out normally. It is recommended to use a pulsed automatic pole-changing electrolysis system, which not only effectively solves the problem of anode passivation, but also helps to loosen and fall off the anode slime. The time adjustment is arbitrarily set by the cycle time relay on the panel of the electrolysis control cabinet.

Scrap Copper Refining System Copper Cathode Production Line

The copper electrolytic treatment and reuse equipment is composed of multiple IGBT automatic power control modules and belongs to digital pulse power equipment. When casting the anode plate, a semi-automatic vertical mold is used. In order to shorten the electrolysis cycle, the thickness of the anode is generally controlled at 10 mm to 30 mm. Anode slime, clean the anode slime, conduct reduction smelting and oxidation smelting in intermediate frequency furnace and blowing furnace, smelted precious metal alloy blocks are crushed by water, and then go through precious metal liquid making to extract, separate and refine various precious metals. In the production workshop, a tail gas absorption device with ozone must be set up in all places where tail gas is generated, and a tail liquid diversion device must be set up in all places where tail liquid is generated, and the tail liquid is diverted to the wastewater treatment workshop and discharged or reused after reaching the standard.

The pure copper obtained by electrolytic copper has a wide range of uses. It is generally suitable for industries that have strict requirements on copper content, such as electrical, light industry, machinery manufacturing, construction industry, national defense industry and other fields. The electrolytic copper obtained by the copper electrolytic recovery and treatment equipment has high purity and wide application, which is a good choice for investment.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou