News

Industrial Copper Wire Granulators

Time:2026-01-06 15:51:20

In the field of scrap metal recycling, cables and wires have always been important raw materials with high copper content and clear recycling value. However, the copper core is tightly covered by insulating layers such as PVC and rubber. If not processed properly, it can lead to incomplete separation, copper loss, and increased labor costs. Henan Recycle's industrial-grade copper wire granulator is an integrated solution designed to address this pain point.

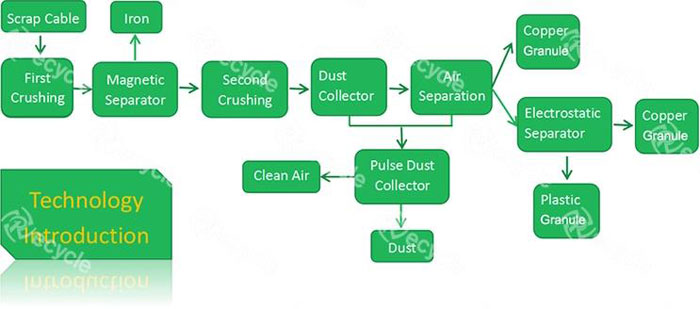

Cable Crushing and Separation Process

The complete copper wire recycling equipment adopts a mature and stable "mechanical crushing + physical separation" process, suitable for various types of scrap wires, including power cables, communication cables, wiring harnesses, and household appliance wires. After entering the system, the material is first processed by a crusher for shearing and tearing, ensuring complete separation of the copper core from the outer insulating material. The crushed mixture then enters the airflow separation system, utilizing the differences in density and wind resistance characteristics between copper and plastic for preliminary separation. Finally, fine screening is performed through a linear vibrating screen, stably outputting high-purity copper granules and PVC plastic granules.

Core Equipment and Technological Advantages

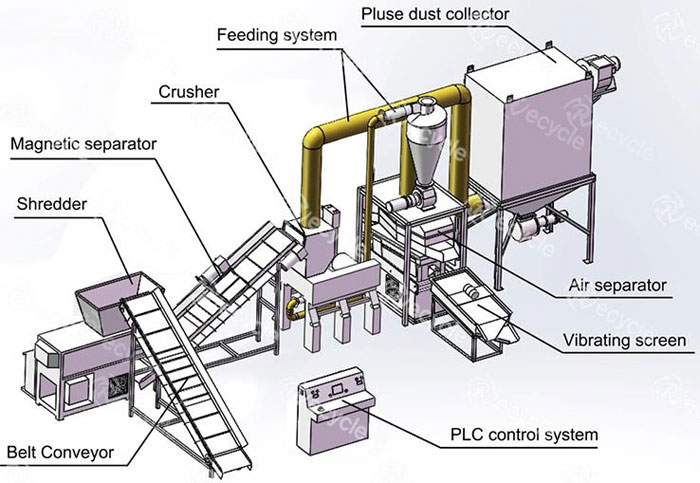

The industrial copper wire granulator mainly consists of a crushing system, an air separation system, a screening system, and a conveying device. The crushing main machine uses wear-resistant tools and an optimized rotation speed design, ensuring sufficient crushing while effectively controlling dust and energy consumption. Airflow separation is the core of the entire production line. By precisely adjusting the airflow and separation channels, copper particles quickly settle down, and light plastic materials are carried away by the airflow, resulting in stable and reliable separation. The linear screen further improves the purity of the finished product, providing quality assurance for subsequent sales or reprocessing. The entire machine has a compact structure, is easy to maintain, and is suitable for continuous and stable operation.

Application Scenarios and Investment Value

This industrial copper wire crushing and separation equipment is widely used in scrap metal recycling stations, resource recovery plants, cable processing enterprises, and other scenarios. The separated copper granules can be directly used in smelting or trading, and the plastic granules also have reuse value, achieving maximum resource recovery. The equipment has a high degree of automation, low reliance on manual labor, controllable long-term operating costs, and a clear return on investment period. For companies that want to stably enter the cable recycling field, this is a mature equipment solution that combines efficiency, purity, and economic benefits.

LATEST NEWS

CONTACT US

Tel: 0086-13674945231(whatsapp)

Email: sunymachine@gmail.com

Add: Henan Communication Industrial Park) 5th St., Economic-Technological Development Zone, Zhengzhou